airtight drywall approach

Airtight drywall approach (ADA) is a building construction technique used to create a continuous air retarder that uses the drywall, gaskets, and caulking. Gaskets are used rather than caulking to seal the drywall at the top and bottom. Although it is an effective energy-saving technique, ADA was designed to keep airborne moisture from damaging insulation and building materials within the wall cavity.

|

Two wall-construction techniques – the airtight drywall approach and simple caulk and seal SCS) – can be used to create a continuous air barrier within a house. Using one of these techniques can significantly reduce air leakage to help improve a home's energy efficiency.

Both ADA and SCS create an effective airtight wall by sealing the drywall to the building structure. To create a continuous air barrier, the exterior sheathing and interior wall finish are sealed to the framing.

The exterior sheathing can be sealed using a variety of methods; caulking the seams of the plywood (or the foam board insulation) is one way. More common is the use of a house wrap or a special tape made specifically for house sheathing. Depending on the climate, additional water vapor control may also be needed. These vapor-control materials often include polyethylene plastic sheeting, faced fiberglass insulation, foil-backed wallboard, or an interior "vapor barrier" paint.

The main difference between the ADA and SCS methods is that with the SCS, seams and gaps are sealed after the exterior sheathing and drywall have been installed and finished. With the ADA, sealing is carried out during the entire construction process.

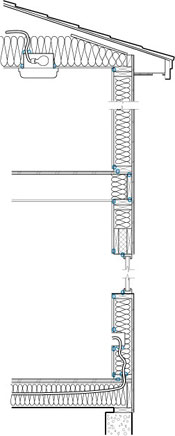

The typical procedure for ADA is to seal any seams and joints where the foundation, sill plate, floor joist header, and sub-floor meet. The spaces between floors, the sub-floor, rim joist, and plates are also sealed. The wall-framing plates are sealed to the lower sub-floor and the upper rim joist. Gaskets are often used at the top and bottom wall plates (between the drywall and framing) and between ceiling drywall and attic joists. Airtight electrical boxes (or standard electrical boxes sealed with caulk) complete the air barrier. Holes where pipes and cables pass through also need to be sealed before the wall and ceiling finishes are applied. After all this has been done and the perimeter drywall seams have been finished, the room is effectively sealed from expensive and uncomfortable drafts.

In some ways, the SCS method is superior to the ADA. The SCS is less disruptive to construction workers, which can speed up the construction process. Sealing after the drywall is finished also provides a drier work environment while sealing. A dry environment can help ensure that the sealing job performs well, since most caulks don't stick to wet surfaces. However, the SCS is less comprehensive than the ADA. The SCS may miss some critical points inside building cavities that become inaccessible after the wall board is installed.

Tests done on both ADA- and SCS-detailed homes indicate that both resulted in similar energy savings. After a year of monitoring, one study found that the ADA house had 0.67–1.80 air changes per hour (ACH) at 50 Pascals pressure. An identical conventional home without ADA had a 2.23–2.59 ACH at 50 Pascals. (Fifty pascals of pressure imitates a 20-mile-per-hour (32-km/hr) wind striking the building from all sides at the same time.)

Such airtight homes often consume one-third less energy when compared to similar unsealed homes. Also, test measurements of airborne contaminants in an ADA- or SCS-detailed building (including those with mechanical ventilation) found that the reduction of air infiltration did not diminish the indoor air quality significantly. However, for health and safety, it is strongly recommended that a heat recovery ventilator (HRV) or enthalpy recovery ventilators (ERV) be installed in an airtight home for proper ventilation.