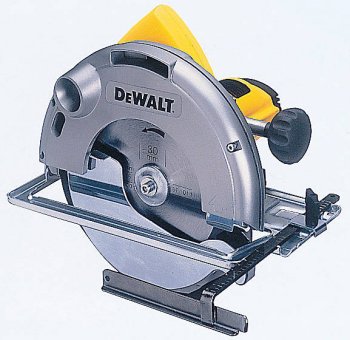

circular saw

A circular saw is a toothed metal disk as well as the machine that makes the disk spin around at high speed. A handheld circular saw is one of the most useful tools for home improvement and renovations. It can be used, for example, to cut a sheet of plywood down to a manageable size. Larger circular saws are bench-mounted. The largest of all are found in saw mills.

Circular saws are normally used to cut wood but can be fitted with special blades to cut masonry, plastics, or metal. There are also purpose-made circular saws designed for particular materials.

Circular saws can be either left- or right-handed, depending on which side of the blade the motor sits.

Types of circular saw

In-line saws are the traditional and commonest kind. In these, the motor housing sits perpendicular to the blade and a shaft runs directly from the motor to drive the blade. In-line saws are well suited to most circular saw applications.

Worm-drive saws are driven indirectly by a motor located parallel with the saw blade. The motor uses gears to increase the torque transferred to the blade, which makes this type of saw a good choice for heavy-duty use.

Cordless circular saws, powered by rechargeable batteries, have become popular in recent years. They're handy when working in areas where extension cords are difficult to use. And, since they are smaller than most corded saws, they work well in confined spaces. Cordless saws are best suited to cutting wood and wood products, due to the limitations of their batteries. They can cut tough materials, but the extra power needed for those applications drains batteries quickly. Cordless saws range in size from 5 3/8" to 6 1/2".

Corded circular saws are better suited for tough cutting jobs such as masonry, steel, and continuous woodcutting. They're available in many sizes, but the most common is 7 1/4".

Features

Among the features to consider are:

What to look for when buying

There are many different styles and models on the market. Choose one that feels comfortable, is not too heavy, and has a well-positioned handle. Look also at the amperage and types of bearings. Top quality saws draw 12 or 13 amps and run on ball bearings. Lower-quality saws use roller or sleeve bearings and are rated about 9 or 10 amps. While plastic housings are not a sign of inferior quality, make sure the saw has extruded or cast metal base plates.

Other questions to ask before purchase: How easy it is to see where the blade is cutting? How easy is it to change the blade? Will it cut bevels? And what attachments, such as a rib fence guide, are available? A guide helps give you a more accurate cut by staying on the right path.

In general, higher quality models and blades may cost more but will prove a better investment over time.