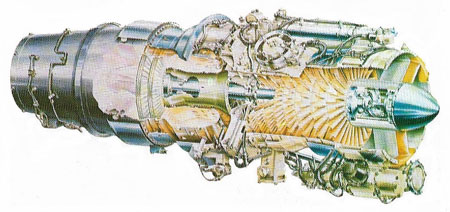

gas turbine

A gas turbine, such as this Rolls-Royce Viper turbojet, uses the hot gases from the burning of fuel to turn sets of turbine blades at the rear of the engine. Other blades, mounted on the same shaft but at the front of the engine, compress the incoming air. Generating up to 4,000 lb. thrust, the engine is used in trainer, light attack and business jet aircraft.

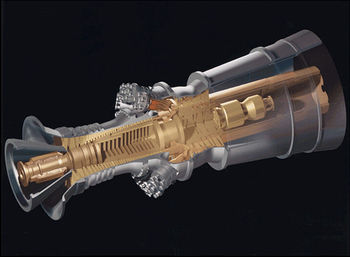

GE H series power generation gas turbine.

A gas turbine is a type of turbine, also known as a combustion turbine, in which combusted, pressurized gas is directed against a series of blades connected to a shaft, which forces the shaft to turn to produce mechanical energy.

Gas turbine plants operate on the Brayton cycle: a thermodynamic cycle that employs constant pressure, heat addition, and heat rejection. (The four basic operations of the Brayton cycle are accomplished simultaneously and continuously for an uninterrupted flow of power.) In a gas turbine, a compressor is used to compress the inlet air upstream of a combustion chamber. Then the fuel is introduced and ignited to produce a high temperature, high-pressure gas that enters and expands through the turbine section. The turbine section powers both the generator and compressor. Combustion turbines are also able to burn a wide range of liquid and gaseous fuels from crude oil to natural gas.

The gas turbine's energy conversion typically ranges from 25% to 35% efficiency as a simple cycle. The simple cycle efficiency can be increased by installing a recuperator or waste heat boiler onto the turbine's exhaust. A recuperator captures waste heat in the turbine exhaust stream to preheat the compressor discharge air before it enters the combustion chamber. A waste heat boiler generates steam by capturing heat form the turbine exhaust. These boilers are known as heat recovery steam generators (HRSG). They can provide steam for heating or industrial processes, which is called cogeneration. High-pressure steam from these boilers can also generate power with steam turbines, which is called a combined cycle (steam and combustion turbine operation). Recuperators and HRSGs can increase the gas turbine's overall energy cycle efficiency up to 80%.

Gas turbine development accelerated in the 1930s as a means of propulsion for jet aircraft. It was not until the early 1980s that the efficiency and reliability of gas turbines had progressed sufficiently to be widely adopted for stationary power applications. Gas turbines range in size from 30 kW (micro-turbines) to 250 MW (industrial frames). Industrial gas turbines have efficiencies approaching 40% and 60% for simple and combined cycles respectively.

The gas turbine share of the (world) power generation market has climbed from 20% to 40% of capacity additions over the past 20 years with this technology seeing increased use for base load power generation. Much of this growth can be accredited to large (>500 MW) combined cycle plants that exhibit low capital cost (less than $550/kW) and high thermal efficiency.