thermal storage systems for concentrating collectors

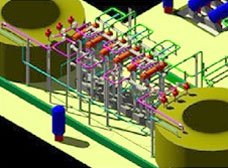

Fig 1. Two-tank direct thermal storage system

One challenge facing the widespread use of solar energy is reduced or curtailed energy production when the sun sets or is blocked by clouds. Thermal energy storage provides a workable solution to this challenge.

In a concentrating solar power (CSP) system, the sun's rays are reflected onto a receiver, which creates heat that is used to generate electricity that can be used immediately or stored for later use. This enables CSP systems to be flexible, or dispatchable, options for providing clean, renewable energy.

Several sensible thermal energy storage technologies have been tested and implemented since 1985. These include the two-tank direct system, two-tank indirect system, and single-tank thermocline system.

Two-tank direct system

Solar thermal energy in this system (Fig 1) is stored in the same fluid used to collect it. The fluid is stored in two tanks – one at high temperature and the other at low temperature. Fluid from the low-temperature tank flows through the solar collector or receiver, where solar energy heats it to a high temperature, and it then flows to the high-temperature tank for storage. Fluid from the high-temperature tank flows through a heat exchanger, where it generates steam for electricity production. The fluid exits the heat exchanger at a low temperature and returns to the low-temperature tank.

Two-tank direct storage was used in early parabolic trough power plants (such as Solar Electric Generating Station I) and at the Solar Two power tower in California. The trough plants used mineral oil as the heat-transfer and storage fluid; Solar Two used molten salt.

Two-tank indirect system

|

| Two-tank indirect thermal storage system |

Two-tank indirect systems function in the same way as two-tank direct systems, except different fluids are used as the heat-transfer and storage fluids. This system is used in plants in which the heat-transfer fluid is too expensive or not suited for use as the storage fluid.

The storage fluid from the low-temperature tank flows through an extra heat exchanger, where it is heated by the high-temperature heat-transfer fluid. The high-temperature storage fluid then flows back to the high-temperature storage tank. The fluid exits this heat exchanger at a low temperature and returns to the solar collector or receiver, where it is heated back to a high temperature. Storage fluid from the high-temperature tank is used to generate steam in the same manner as the two-tank direct system. The indirect system requires an extra heat exchanger, which adds cost to the system.

This system will be used in many of the parabolic power plants in Spain and has also been proposed for several U.S. parabolic plants. The plants will use organic oil as the heat-transfer fluid and molten salt as the storage fluid.

Single-tank thermocline system

|

| Single-tank thermocline thermal storage system. |

Single-tank thermocline systems store thermal energy in a solid medium – most commonly, silica sand – located in a single tank. At any time during operation, a portion of the medium is at high temperature, and a portion is at low temperature. The hot- and cold-temperature regions are separated by a temperature gradient or thermocline. High-temperature heat-transfer fluid flows into the top of the thermocline and exits the bottom at low temperature. This process moves the thermocline downward and adds thermal energy to the system for storage. Reversing the flow moves the thermocline upward and removes thermal energy from the system to generate steam and electricity. Buoyancy effects create thermal stratification of the fluid within the tank, which helps to stabilize and maintain the thermocline.

Using a solid storage medium and only needing one tank reduces the cost of this system relative to two-tank systems. This system was demonstrated at the Solar One power tower, where steam was used as the heat-transfer fluid and mineral oil was used as the storage fluid.