Iron Age

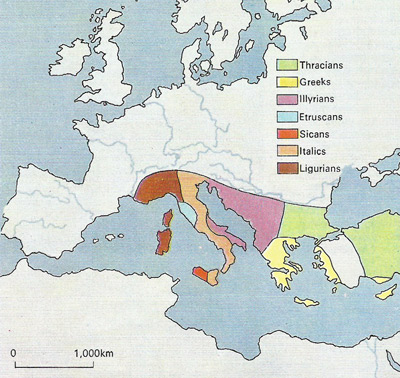

Figure 1. Iron ores are very common and widespread, second only to those of aluminum. But early Iron Age man would not have used the richer ores such hematite and magnetite, which can contain as much as 60% iron. These ores must be mined. He would probably have first exploited bog iron ore which, as it name implies occurs freely in marshy ground. It is formed by the decomposition of other iron minerals and is finally precipitated in the water by the action of bacteria. It needs only to be sieved out to be used. However, by 850 BC several other iron ores were being worked in Europe, and this map shows the regions occupied by various peoples who worked iron ore.

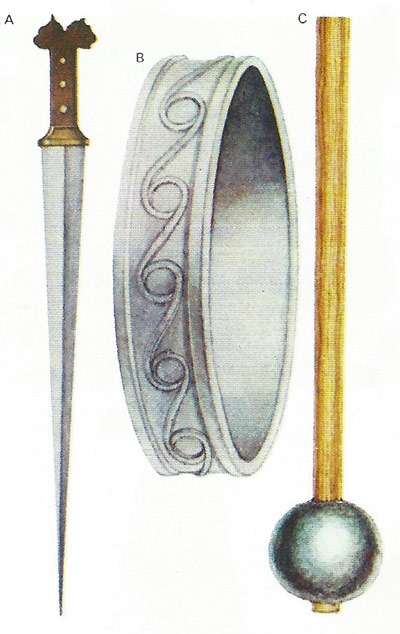

Figure 2. Earliest of man-made objects were ornaments and small weapons, dating from before 2500 BC. The Hittite dagger-sword (A) was made somewhat later. Its blade would have been beaten out from heated iron ore. This produced a relatively crude form of iron but the Hittite smiths eventually became the masters of iron technology. They influenced European ironwork, such as this collar (B). By 500 BC, in Styria and Carinthia, central Europe, ironsmiths were making a kind of steel by hammering charcoal (a form of carbon) into heated iron. The iron-headed mace (C) is a late example of primitive iron technology from Chieti, Italy. It dates from about 600 BC.

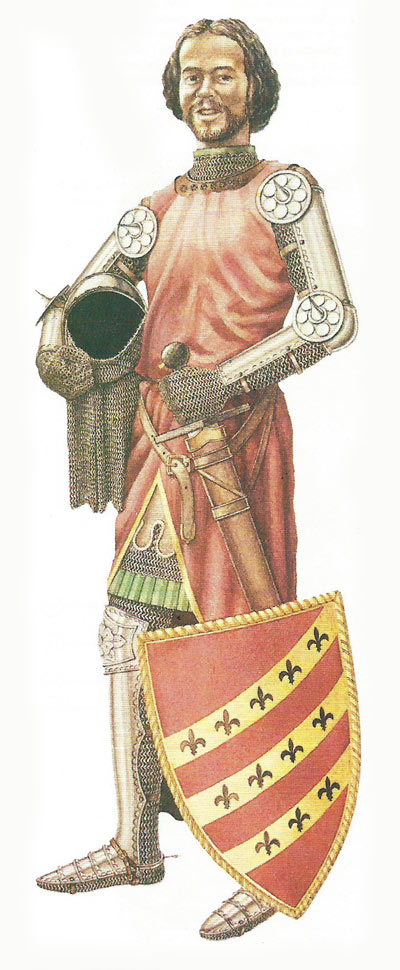

Figure 3. After the fall of the Roman Empire, metalworking in Europe declined, surviving mainly in the elegant iron swords made by the Burgundian and Frankish smiths, which had patterns formed by strips of welded iron. The horsemen of Charlemagne, king of the Franks in the 8th century AD, were clothed in a heavy iron armor of a design that owed little to the Romans; the Germanic conquerors of the Roman Empire had apparently despised the thought of copying armor of a defeated foe. Chain mail came later still as an import from the East. This feudal knight wears up to 50 kg (110 lb) of mail and plate. Mail was made from rings of iron wire riveted or welded together and shaped to cover the arms, feet, and head. By the 14th century, plate armor, originally a reinforcement for chain mail, was beginning to take its place. Ironsmiths were by this time adept at shaping accurately the joints necessary for plate armor and were also skilled at producing decorative metal inlays.

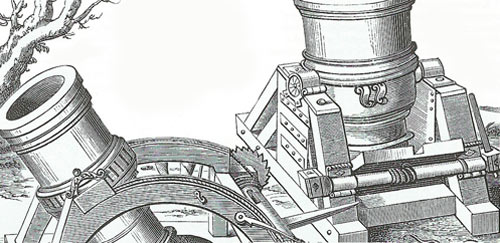

Figure 4. The first iron cannon and mortars were brittle and likely to blow up in the user's face. From the 15th century they were cast in a more reliable iron.

Figure 5. Coke smelting was first introduced by Abraham Darby in Coalbrookdale, England in the early 18th century. It replaced the use of charcoal, which was dependent on failing supplies of wood, and greatly accelerated England's rapid industrial development.

The Iron Age was the stage of human material cultural development, following the Stone Age and Bronze Age, during which iron is generally used for weapons and tools. Though used ornamentally as early as 4000 BC in Egypt and Mesopotamia, iron's difficulty of working precluded its general use until efficient techniques were developed in Armedia, c. 1500 BC. By c. 500 BC the use of iron was dominant throughout the known world, and by c. 300 BC the Chinese were using cast iron. Some cultures, as those in America and Australia, are said never to have had an Iron Age.

Dawn of the Iron Age

Humans might first have encountered iron as a gift from the heavens: iron meteorites could have supplied the metal for weapons and ornaments made in about 3000 BC or even earlier. The manufacture of iron tools had to wait another thousand years until the introduction of iron smelting – the extraction of the often impure metal from iron ores. Iron's high melting temperature means that it cannot be melted directly over a wood or coal fire. Some kind of forced-draft, or blast, furnace must be used to reach the required temperature of 1,539°C (2,802°F).

Primitive smelting ovens did produce a malleable iron of fair quality and were used for several centuries in different countries. Iron was of fundamental importance to a number of civilizations and by the first century AD the Noricans, Parthians, and Chinese were able to produce mild steel.

The methods of the Hittite smiths

Iron in the form of bog ore is quite plentiful, widespread and easy to get at. To make iron objects the ore is first smelted to make a "bloom" of iron. It must then be heated and hammered to remove the slag, then quenched in water. This process, repeated several times, makes iron of adequate strength. The technique was used widely by Hittite ironsmiths, the first true technologist of the Iron Age, in the second millennium BC.

These Hittites closely guarded their smelting method but the destruction of the Hittite Empire in 1200 BC the smiths were scattered, so that other tribes and nations benefitted from their skill in making tough metal tools. At this time a kind of steel – iron containing 1.5 percent or less of carbon – had also been made and was used for tools and weapons needing a sharp cutting edge. An early Iron Age spearhead or sickle was limited by lack of a socket, which could be made only by casting the metal in a mold. A few socketed iron weapons have been found dating from as early as the second millennium BC but their sockets are made from gold or copper (copper melts at 1,083°C and gold at 1,064°C, so these metals could be melted over a fire for casting). Iron swords of this period were stronger and less brittle than bronze ones.

More peaceful early Iron Age objects include the tongs, hammers, and anvils used by the ironsmiths themselves, and iron nails, a great improvement on bronze nails that were of only limited strength.

The first iron plowshares, from Palestine, date from about 1100 BC but the Greeks of the sixth century BC, do not seem to have used iron for this purpose and iron-shod plows became common only in Roman times. By 600 BC the Catalans of northeastern Spain were able to soften, but not melt, iron in a type of furnace having a forced draft provided by bellows.

Romans and their use of iron

If the Hittites were the first ironsmiths, then the Romans were the first mining engineers. Sites of Roman metal mines range from southern Scotland to southern Spain in the west to Romania in the east.

As would be expected, Roman iron and steel were put to many military uses. The famous short-sword, the nine-foot spear, and the cuirass inherited from the Greeks were all made largely of iron. Later Roman soldiers also used iron long-swords and throwing spears and shot iron darts from their catapults. Iron-headed battering-rams had been used since the time of the Assyrians; a Roman improvement was the terebra which bored into battered walls and gates.

In architecture the Greeks had made the most imaginative use of iron, in wrought-iron beams. In the construction of the Parthenon, such beams acted as cantilevers which held up the heaviest statues on the pediment. The Romans later made use of T-shaped iron girders, as in the Baths of Caracalla where they help to support a dome 36 meters (118 feet) across.

Little is known about mining and metallurgy in the early Middle Ages except that Saxon miners were at work in the Harz mountains before AD 1000. Knowledge of later medieval mining technology is much greater, due largely to a single man, the Saxon physician usually known as Agricola. His great book De re metallica (1556) details methods and machinery and demonstrates that mining was a profitable industry.

Centuries before Agricola's time, the iron industry was lively but was what today would be called an armaments industry. From the time of Charlemagne (AD 742–814) onwards, iron armor was invented and afresh, very little being copied from the Romans. Later there evolved a totally new iron technology – the manufacture of iron firearms.

Iron smelting and casting

The final great discovery of the Iron Age was that iron could be melted and cast in molds. The first blast furnaces were developed as enlarged versions of medieval Stückofen. They used first charcoal, and then coal, both as fuel and as a necessary ingredient (carbon) for the smelting process. By 1711, Abraham Darby in Coalbrookdale, England, began to use coke to smelt large quantities of ores to make good-quality cast iron suitable for forging as well as for casting in sand molds. Previously, cast utensils, such as pots, could be made only from expensive metals such as brass. Soon every home in the land had cast-iron cooking pots and pans. Iron was used for making bridges and railways. The Industrial Revolution and the age of steel had begun.