turbine

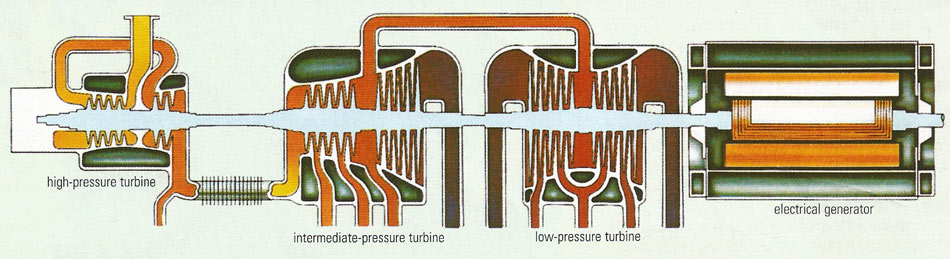

Turbines and generators are the components that convert the rotary motion produced by steam or water power into electricity. To obtain the maximum energy from the water or steam, there are several stages of turbines – up to five in a large power station – each using water or steam at a slightly lower pressure than the previous one. Super-heated steam at up to 600°C (1,112°F) gives up much of its energy in a high-pressure turbine. The exhaust steam from this stage is reheated and passed to an intermediate-pressure turbine and then to a low-pressure turbine. The output shaft drives a generator.

A turbine is a machine for directly converting the kinetic and/or thermal energy of a flowing fluid into useful rotational energy. The working fluid may be air, hot gas, steam, or water. This either pushes against a set of blades mounted on the drive shaft (impulse turbines) or turns the shaft by reaction when the fluid is expelled by nozzles (or nozzle-shaped vanes) around its circumference (reaction turbines).

Water turbines were the first to be developed. They now include the vast inward-flow reaction turbines used in the generation of hydroelectricity and the smaller-scale tangential flow Pelton wheel impulse types used when exploiting a very great head of water.

In the 1880s, Charles Algernon Parsons (1854–1931), a British engineer, designed the first successful steam turbines, having realized that the efficient use of high-pressure steam demanded that its energy be extracted in a multitude of small stages. Steam turbines thus consist of a series of vanes mounted on a rotating drum with stator vanes redirecting the steam in between the moving ones. They are commonly used as marine engines and in thermal and nuclear power plants. Gas turbines are not yet as widely used except in airplanes and for peak-load electricity generation.