carbon fiber

Carbon fiber is a form of carbon made by heating textile fibers to very high temperatures. The result is fibers (typically 0.001 cm in diameter) which are, weight-for-weight, some of the strongest of all fibers. They are too short to be woven into super-strong yarn. Instead they are incorporated into plastics, ceramics, and glass, which give the materials great strength and resistance to breakage.

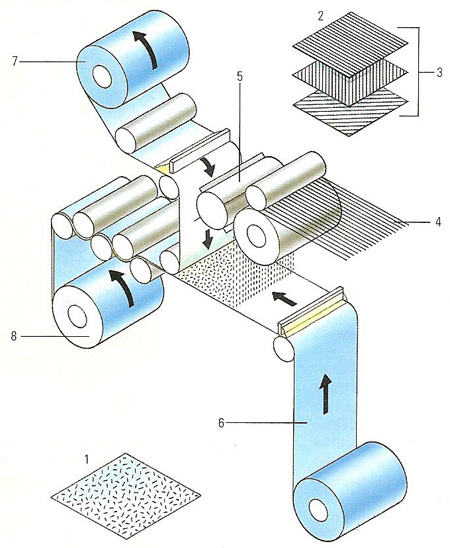

Carbon fiber composites combine twisted carbon fibers with a resin to produce a material up to four times stronger than steel for its weight. Two main forms exist. The carbon fiber is either chopped into short lengths and attached to the resin backing at random (1) or laid down in strips (2). The former has strength in all directions but the latter has great strength against the grain in different directions to give overall strength in all directions (3). Strands of twisted carbon (4) pass through a chopper (5) and fall onto a backing material (6) coated with the bonding resin (7). Another layer of resin and backing material is then laid on top and the composite is rolled for storage (8).