nylon

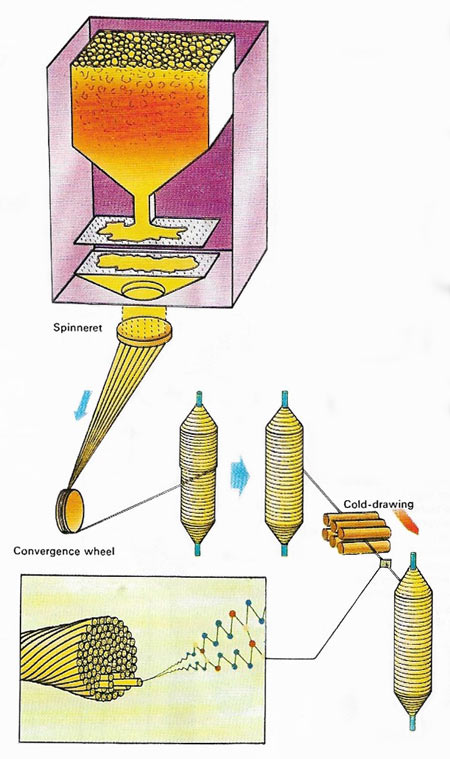

Manufacture of nylon.

Nylon is any of a group of polymers containing amide groups recurring in the chain (polyamides). Nylon is chemically inert, heat-resistant, tough, elastic, and very strong, and is extruded and drawn to make synthetic fibers, filaments, and bristles, rolled out as sheets, or cast and molded into bearings, gears, zippers, etc. Developed in the US in the 1930s, it is used chiefly in yarn, cordage, and molded products. Hard and tough or soft and rubbery nylon products can be made by varying their composition.

Making nylon

In making nylon two chemical compounds, such as hexamethylenediamine and adipic acid, are melted and combined under pressure in a hopper. The liquid nylon thus formed is filtered through metal gauze or sand and extruded as very fine filaments, or strands, through a spinneret. The filaments are twisted and united into yarn by a convergence wheel, which feeds the yarn on to bobbins. It is then cold-drawn, or stretched, to alter the molecular structure of the yarn filaments and this gives them greater strength and elasticity. This process is carried out by unwinding the yarn from one bobbin, passing it through rollers to stretch it and then winding it on to another bobbin.