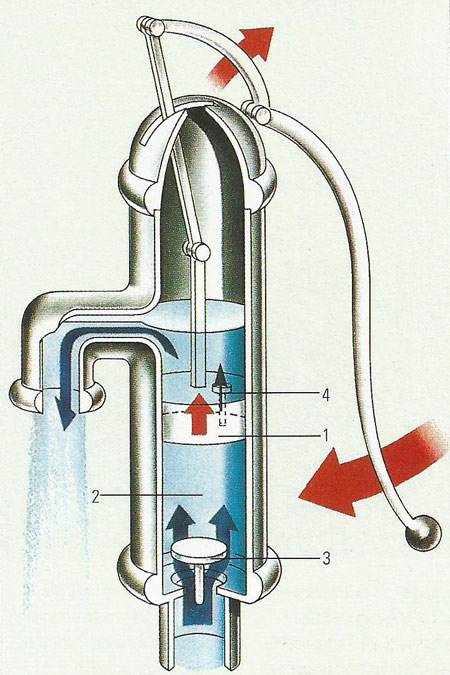

pump

A typical lift pump, such as the ones that were commonly used to raise water from an underground supply, work by employing two one-way valves. As the handle is pumped back and forth the action is converted into the reciprocal, up-and-down motion of the plunger (1). As the plunger moves up it creates a partial vacuum in a collecting chamber (2), into which water is sucked. As the plunger descends, a valve (3) prevents the water being forced down the bore hole, while a second valve (4) allows the water to flow through the plunger which, when it rises again, forces water from the pump outlet.

A pump is a device for taking and forcing out a fluid, thus giving it kinetic or potential energy. The heart is a pump for circulating blood around the body. Pumps are commonly used domestically and industrially to transport fluids, to raise liquids, to compress gases, or to evacuate sealed containers. Their chief use is to force fluids along pipelines.

The earliest pumps were waterwheels, endless chains of buckets, and the Archimedes screw. Piston pumps, known in classical times, were developed in the 16th and 17th centuries, the suction types (working by atmospheric pressure) being usual, though unable to raise water more than about 10.4m (34ft).

The steam engine was developed to power pumps for pumping out mines. Piston pumps – the simplest of which is the syringe – are reciprocating volume-displacement pumps, as are diaphragm pumps, with a pulsating diaphragm instead of the piston. One-way inlet and outlet valves are fitted in the cylinder. Rotary volume-displacement pumps have rotating gear wheels or wheels with lobes or vanes. Kinetic pumps, or fans, work by imparting momentum to the fluid by means of rotating curved vanes in a housing: centrifugal pumps expel the fluid radially outward, and propeller pumps axially forward.

Air compressors use the turbine principle. Air pumps use compressed air to raise liquids from the bottom of wells, displacing one fluid by another. If the fluid must not come into direct contact with the pump, as in a nuclear reactor, electromagnetic pumps are used: an electric current and a magnetic field at right angles induce the conducting fluid to flow at right angles to both (see electric motor); or the principle of the linear induction motor may be used. To achieve a very high vacuum, the diffusion pump is used, in which atoms of condensing mercury vapor entrain the remaining gas molecules.