mass production

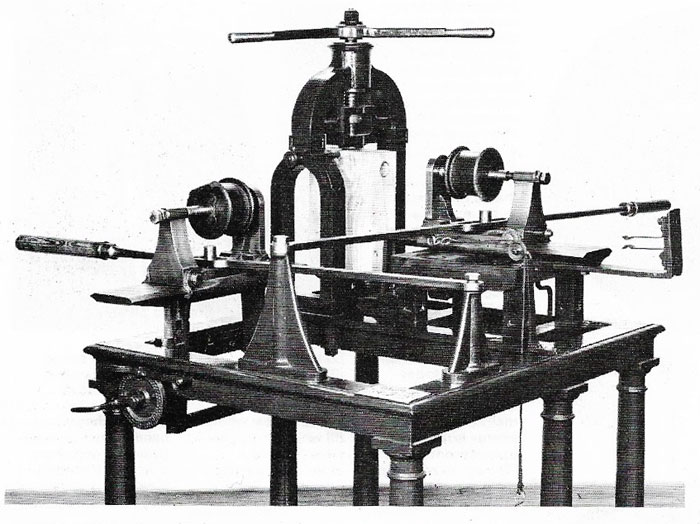

Figure 1. The machinery that was set up in the Royal Dockyard at Portsmouth was the first instance of the use of mass production of interchangeable parts with machine tools. The machines were so well designed and built that several of them were still in use in the 1950s. The total saving in the first year was £24,000 of which the inventor, Marc Isambard Brunel received £17,000.

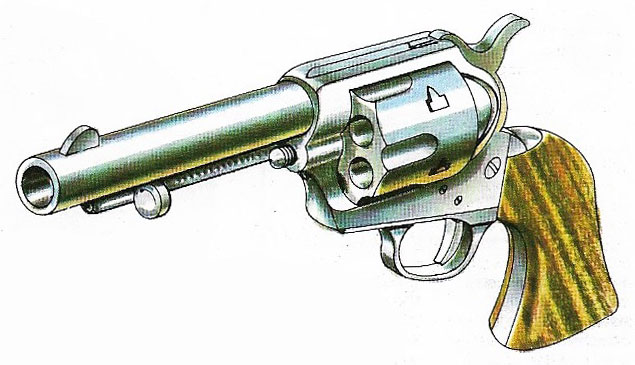

Figure 2. The 1873 Colt revolver is still being made today. Colonel Samuel Colt (1814–1862) was the first mass-producer of firearms. His revolvers had single-action mechanisms and therefore had to be cocked before firing. They were first supplied in .44-inch caliber to the US Army after the Mexican War (1846–1848).

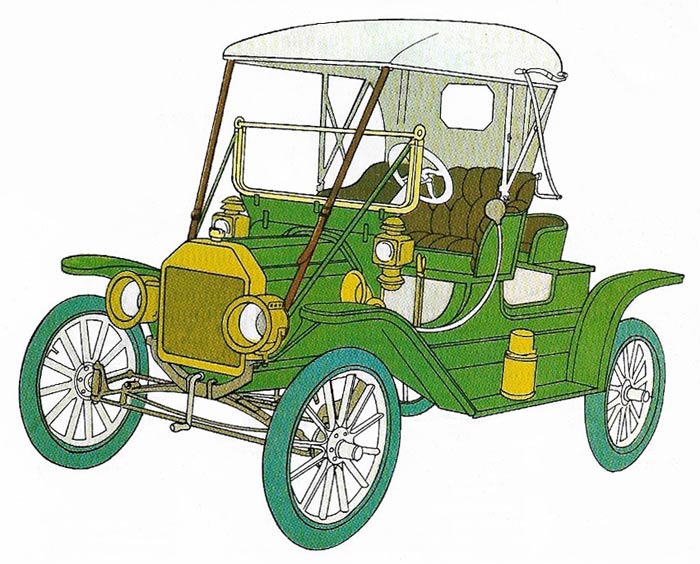

Figure 3. The Model T Ford was first manufactured in 1908.Fifteen million cars were sold during its 19 years of production. With the Model T, mass production could be said to have come of age.

Mass production is the production of large numbers of identical objects, usually by use of mechanization. The root of mass production is the assembly line, essentially a conveyor belt which transports the product so that each worker or robot may perform a single function on it (e.g., add a component). The advantages of mass production are cheapness and speed; the disadvantages are the lack of job satisfaction for the workers and the resultant numerical control machines.

History of the factory system

Underlying the organization of a factory is the principle of the division of labor, formulated by Adam Smith (1723–1790) in his book The Wealth of Nation (1776), in which he described methods used to make pins. In Europe the factory system became firmly established for the making of cloth in the seventeenth century. The process was subdivided into carding, spinning,and weaving, sometimes with many machines in one factory. Even so, factory production accounted for only a small proportion of the total output of cloth.

A decisive step came with the design and manufacture of machinery with standardized interchangeable parts. In 1803 Marc Isambard Brunel designed machinery with interchangeable parts for making pulley-blocks for the Portsmouth naval dockyard (Figure 1). The machinery was manufactured by Henry Maudsley and there were 45 machines of 22 different kinds. By 1807 the machinery was capable of supplying the entire pulley-block requirements of the Royal navy and by 1808 there was a yearly production rate of 130,000 blocks.

in 1798, US inventor Eli Whitney introduced mass production when he was given the contract to make 10,000 guns for the US Army (Figure 2). Whitney built machinery to make identical parts for all the guns, so that all the components could be produced quickly and were guaranteed to fit. It also meant that damaged parts could be replaced with standard spares. The assembly line, with a conveyor belt carrying the work through a series of assembly areas, is another feature of mass-production processes. In 1912 Henry Ford used this system in Detroit for the mass production of his Model T car (Figure 3). Many modern mass-production processes depend on computer control of machines, including robots.