turbojet engine

The turbojet engine was the first type of jet engine to be developed and one that, in various forms, has remained in widespread use to this day. The turbojet was invented by Frank Whittle in England and, independently, by Hans von Ohain in Germany.

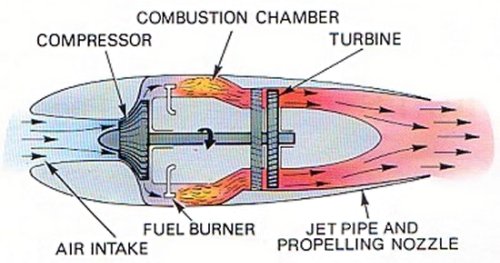

Air is drawn into the turbojet by a compressor, which is basically a large spinning fan. The compressor slows down the incoming air, raising its pressure, and delivers it to the combustion chamber. Fuel is injected into the high-pressure air in the combustion chamber and ignited. The resulting hot gases expand and rush first through a turbine and then through a jet pipe and nozzle at the rear. Forward thrust is generated as a reaction to the rearward momentum of the exhaust gases.

Before the expanding gases are allowed to escape out of the rear of the engine, they are directed onto the blades of a turbine rotor which they cause to rotate at high speed. The purpose of the turbine is to drive the compressor to which it is attached by a shaft, thereby enabling the compressor to continually draw in more air. Thus, the air which is compressed and then heated in the combustion chamber is not only used to provide a forward thrust but also to drive the turbine that drives the compressor that compresses the air.

The trouble with making the exhaust gases drive a turbine is that the forward thrust depends upon the difference in pressure between the closed and open ends of the combustion chambers, and if the escaping gases have to push against something (the turbine blades) that difference in pressure is lessened. In other words, a pressure at the rear detracts from the forward thrust. Thus, the designer's aim in a turbojet engine is to reduce to a minimum the power taken by the turbine to compress the air so that the maximum amount of forward thrust is available.

To substantially increase the thrust of a turbojet, most notably for use in military jet aircraft, an afterburner can be added.

Dual spool engine and variable stator

The earliest jet engines, such as those of the Messerschmidt 262, were very fuel thirsty, so one of the first challenges to designers was coming up with an engine that could deliver high thrust with lower fuel consumption. A solution to this problem came from the American company Pratt & Whitney in 1948 with its "dual spool" concept. The dual spool engine was equipped with two, independently-rotating compressors instead of one in order to increase the pressure ratio. The two systems were connected independently to turbine disks at the rear. The low-pressure compressor was connected to the rear turbine disks by a solid shaft, while the high-pressure compressor was connected to the inner turbine disk by a hollow shaft. This approach led to the J-57 engine, which entered service with the U.S. Air Force in 1953 and powered the F-100, the first aircraft to break the sound barrier without going into a dive. J-57s also powered the B-52 bomber and the U-2 spy plane, and, among commercial airliners, the Boeing 707 and Douglas DC-8. The dual spool engine was a direct ancestor of the turbofan.

As the performance of jet engines increased, designers had to confront another problem in the form of "compressor stall". This meant that at certain speeds while in flight, the compressor would pull in more air than the rest of the engine could swallow. Compressor stall produced a sudden blast of air that rushed forward within the engine. The engine lost all its thrust, while this air blast sometimes caused severe damage by breaking off compressor blades. A way to eliminate compressor stall was found by Gerhard Neumann, an engineer with General Electric. Neumann invented the variable stator – a set of small vanes that protruded into the airflow within the compressor. Each vane was like a hand stuck outside a fast-moving car. It was mounted as if to a wrist. When the vanes faced the airflow with their edges forward, they allowed the flow to pass them freely. But when the vanes were turned with their broad faces to the flow, they partially blocked it, reducing the amount of flow that could pass through the compressor and keeping it from gulping in too much air. The variable stator was used General Electric's J-79, the first true engine for supersonic flight.