corrosion

Figure 1. A heavily corroded pipeline.

Figure 2. Electrical isolation flanges like those shown above are used to prevent galvanic corrosion. Insulating gaskets, usually polymers, are inserted between the flanges, and insulating sleeves and washers isolate the bolted connections.

Figure 3. The rust bubbles or tubercules on the cast iron indicate that pitting is occurring. Researchers have found that the environment inside the rust bubbles is almost always higher in chlorides and lower in pH (more acidic) than the overall external environment. This leads to concentrated attack inside the pits.

Figure 4. Sometimes pitting corrosion can be quite small on the surface and very large below the surface. This effect is common on stainless steels and other film-protected metals.

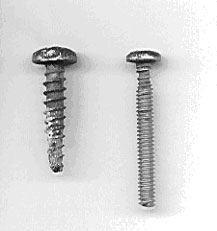

Figure 5. Screws and fasteners are common sources of crevice corrosion problems. These stainless steel screws corroded in the moist atmosphere of a pleasure boat hull.

Figure 6. This picture shows stainless steel which corroded in the heat affected zone a short distance from the weld. This is typical of intergranular corrosion in austenitic stainless steels. This corrosion can be eliminated by using stabilized stainless steels or by using low-carbon stainless grades.

Figure 7. Erosion corrosion due to fast fluid flow past an oil-field check valve.

Figure 8. Cracking and staining of a seawall near the Kennedy Space Center.

Figure 9. A "rusticle" removed from the hull of Titanic. This combination of rust and organic debris clearly shows the location of rivet holes and where two steel plates overlapped.

Corrosion is the insidious destruction of metals and alloys by chemical reaction (mainly oxidation)

with the environment. In moist air most metals form a surface layer of oxide,

which, if it is coherent, may slow down or prevent further corrosion (Fig 1).

The term "corrosion" can be applied generally to mean the degradation

of any material, including polymers (plastics, rubbers, etc), ceramics

(concrete, brick, etc), and composites (mechanical mixtures of two or more

materials with different properties. For example, the cracking of a polymer

due to sunlight is a form of corrosion. However, most of what follows applies

specifically to the corrosion of metals and alloys.

Tarnishing is the formation of such a discolored layer, mainly on copper or silver. (Rust – hydrated iron (III) oxide, FeO(OH) – offers little protection, so that iron corrodes rapidly.) Industrial air pollution greatly speeds up corrosion, oxidizing and acid gases (especially sulfur dioxide) being the worst culprit. Corrosion is usually an electrochemical process: small cells are set up in the corroding metal, the potential difference being due to the different metals present or to different concentrations of oxygen or electrolyte; corrosion takes place at the anode. It also occurs preferentially at grain boundaries and where the metal is stressed.

Prevention methods include bonderizing; a protective layer of paint, varnish, or electroplate; or the use of a "sacrificial anode" of zinc or aluminum in electrical contact with the metal, that is preferentially corroded. Galvanizing – coating iron objects with zinc – works on the same principle.

Types of corrosion

There are various ways of describing the forms that corrosion may take. The classification described below is the one adopted by the Corrosion Control Laboratory at NASA's Kennedy Space Center. No universally-accepted terminology is in use.

Uniform corrosion

Also called general corrosion, this is the surface effect produced by most direct chemical attacks (e.g., by an acid) resulting in a uniform etching of the metal. On a polished surface, this type of corrosion is first seen as a general dulling of the surface and, if allowed to continue, the surface becomes rough and possibly frosted in appearance. The discoloration or general dulling of metal created by its exposure to elevated temperatures is not to be considered as uniform etch corrosion. The use of chemical-resistant protective coatings or more resistant materials will control these problems. While this is the most common form of corrosion, it is generally of little engineering significance, because structures will normally become unsightly and attract maintenance long before they become structurally affected.

Galvanic corrosion

Galvanic corrosion is an electrochemical action of two dissimilar metals in the presence of an electrolyte and an electron conductive path. It occurs when dissimilar metals are in contact. It is recognizable by the presence of a buildup of corrosion at the joint between the dissimilar metals. For example, when aluminum alloys or magnesium alloys are in contact with steel (carbon steel or stainless steel), galvanic corrosion can occur and accelerate the corrosion of the aluminum or magnesium. This can be seen on the photo above where the aluminum helicopter blade has corroded near where it was in contact with a steel counterbalance.

The natural differences in metal potentials produce galvanic differences, such as the galvanic series in sea water. If electrical contact is made between any two of these materials in the presence of an electrolyte, current must flow between them. The farther apart the metals are in the galvanic series, the greater the galvanic corrosion effect or rate will be. Metals or alloys at the upper end are noble while those at the lower end are active. The more active metal is the anode or the one that will corrode.

Control of galvanic corrosion is achieved by using metals closer to each other in the galvanic series or by electrically isolating metals from each other (Fig 2). Cathodic protection can also be used to control galvanic corrosion effects.

Concentration cell corrosion

Concentration cell corrosion occurs when two or more areas of a metal surface are in contact with different concentrations of the same solution. There are three general types of concentration cell corrosion:

Metal ion concentration cells

In the presence of water, a high concentration of metal ions will exist under faying surfaces and a low concentration of metal ions will exist adjacent to the crevice created by the faying surfaces. An electrical potential will exist between the two points. The area of the metal in contact with the low concentration of metal ions will be cathodic and will be protected, and the area of metal in contact with the high metal ion concentration will be anodic and corroded. This condition can be eliminated by sealing the faying surfaces in a manner to exclude moisture. Proper protective coating application with inorganic zinc primers is also effective in reducing faying surface corrosion.

Oxygen concentration cells

A water solution in contact with the metal surface will normally contain dissolved oxygen. An oxygen cell can develop at any point where the oxygen in the air is not allowed to diffuse uniformly into the solution, thereby creating a difference in oxygen concentration between two points. Typical locations of oxygen concentration cells are under either metallic or nonmetallic deposits (dirt) on the metal surface and under faying surfaces such as riveted lap joints. Oxygen cells can also develop under gaskets, wood, rubber, plastic tape, and other materials in contact with the metal surface. Corrosion will occur at the area of low-oxygen concentration (anode). The severity of corrosion due to these conditions can be minimized by sealing, maintaining surfaces clean, and avoiding the use of material that permits wicking of moisture between faying surfaces.

Active-passive cells

Metals that depend on a tightly adhering passive film (usually an oxide) for corrosion protection; e.g., austenitic corrosion-resistant steel, can be corroded by active-passive cells. The corrosive action usually starts as an oxygen concentration cell; e.g., salt deposits on the metal surface in the presence of water containing oxygen can create the oxygen cell. If the passive film is broken beneath the salt deposit, the active metal beneath the film will be exposed to corrosive attack. An electrical potential will develop between the large area of the cathode (passive film) and the small area of the anode (active metal). Rapid pitting of the active metal will result. This type of corrosion can be avoided by frequent cleaning and by application of protective coatings.

Pitting corrosion

Passive metals, such as stainless steel, resist corrosive media and can

perform well over long periods of time. However, if corrosion does occur,

it forms at random in pits (Figures 3 and 4). Pitting is most likely to occur in the presence

of chloride ions, combined with such depolarizers as oxygen or oxidizing

salts. Methods that can be used to control pitting include maintaining clean

surfaces, application of a protective coating, and use of inhibitors or

cathodic protection for immersion service. Molybdenum additions to stainless

steel (e.g., in 316 stainless) are intended to reduce pitting corrosion.

Similar changes in environment occur inside crevices, stress corrosion cracks,

and corrosion fatigue cracks. All of these forms of corrosion are sometimes

included in the term occluded cell corrosion.

Crevice corrosion

Crevice or contact corrosion is the corrosion produced at the region of contact of metals with metals or metals with nonmetals. It may occur at washers, under barnacles, at sand grains, under applied protective films, and at pockets formed by threaded joints (Figure 5). Whether or not stainless steels are free of pit nuclei, they are always susceptible to this kind of corrosion because a nucleus is not necessary.

Cleanliness, the proper use of sealants, and protective coatings are effective means of controlling this problem. Molybdenum-containing grades of stainless steel have increased crevice corrosion resistance.

Filiform corrosion

This type of corrosion occurs under painted or plated surfaces when moisture permeates the coating. Lacquers and "quick-dry" paints are most susceptible to the problem. Their use should be avoided unless absence of an adverse effect has been proven by field experience. Where a coating is required, it should exhibit low water vapor transmission characteristics and excellent adhesion. Zinc-rich coatings should also be considered for coating carbon steel because of their cathodic protection quality.

Filiform corrosion normally starts at small, sometimes microscopic, defects in the coating. Lacquers and "quick-dry" paints are most susceptible to the problem. Their use should be avoided unless absence of an adverse effect has been proven by field experience. Where a coating is required, it should exhibit low water vapor transmission characteristics and excellent adhesion. Zinc-rich coatings should also be considered for coating carbon steel because of their cathodic protection quality.

Filiform corrosion is minimized by careful surface preparation prior to coating, by the use of coatings that are resistant to this form of corrosion, and by careful inspection of coatings to insure that holidays, or holes, in the coating are minimized.

Intergranular corrosion

Intergranular corrosion is an attack on or adjacent to the grain boundaries of a metal or alloy (Figure 6). A highly magnified cross section of most commercial alloys will show its granular structure. This structure consists of quantities of individual grains, and each of these tiny grains has a clearly defined boundary that chemically differs from the metal within the grain center. Heat treatment of stainless steels and aluminum alloys accentuates this problem. Heat-treatable aluminum alloys can also have this problem.

Exfoliation corrosion

Exfoliation is a form of intergranular corrosion. It manifests itself by lifting up the surface grains of a metal by the force of expanding corrosion products occurring at the grain boundaries just below the surface. It is visible evidence of intergranular corrosion and most often seen on extruded sections where grain thickness is less than in rolled forms. This form of corrosion is common on aluminum, and it may occur on carbon steel.

Stress corrosion cracking

Stress corrosion cracking (SCC) is caused by the simultaneous effects of tensile stress and a specific corrosive environment. Stresses may be due to applied loads, residual stresses from the manufacturing process, or a combination of both.

Cross sections of SCC frequently show branched cracks. This river branching pattern is unique to SCC and is used in failure analysis to identify when this form of corrosion has occurred.

Corrosion fatigue

Corrosion fatigue is a special case of stress corrosion caused by the combined effects of cyclic stress and corrosion. No metal is immune from some reduction of its resistance to cyclic stressing if the metal is in a corrosive environment. Damage from corrosion fatigue is greater than the sum of the damage from both cyclic stresses and corrosion. Control of corrosion fatigue can be accomplished by either lowering the cyclic stresses or by corrosion control.

Erosion corrosion

Erosion corrosion is the result of a combination of an aggressive chemical environment and high fluid-surface velocities (Fig 7). This can be the result of fast fluid flow past a stationary object, or it can result from the quick motion of an object in a stationary fluid, such as happens when a ship's propeller churns the ocean.

Surfaces which have undergone erosion corrosion are generally fairly clean, unlike the surfaces from many other forms of corrosion.

Erosion corrosion can be controlled by the use of harder alloys (including flame-sprayed or welded hard facings) or by using a more corrosion resistant alloy. Alterations in fluid velocity and changes in flow patterns can also reduce the effects of erosion corrosion.

Erosion corrosion is often the result of the wearing away of a protective scale or coating on the metal surface. The oil field production tubing shown above on the right corroded when the pressure on the well became low enough to cause multiphase fluid flow. The impact of collapsing gas bubbles caused the damage at joints where the tubing was connected and turbulence was greater.

Many people assume that erosion corrosion is associated with turbulent flow. This is true, because all practical piping systems require turbulent flow-the fluid would not flow fast enough if lamellar (nonturbulent) flow were maintained. Most, if not all, erosion corrosion can be attributed to multiphase fluid flow.

Dealloying

Dealloying is a rare form of corrosion found in copper alloys, gray cast iron, and some other alloys. Dealloying occurs when the alloy loses the active component of the metal and retains the more corrosion resistant component in a porous "sponge" on the metal surface. It can also occur by redeposition of the noble component of the alloy on the metal surface. Control is by the use of more resistant alloys-inhibited brasses and malleable or nodular cast iron.

Hydrogen damage

Hydrogen can cause a number of corrosion problems. Hydrogen embrittlement is a problem with high-strength steels, titanium, and some other metals. Control is by eliminating hydrogen from the environment or by the use of resistant alloys.

Hydrogen blistering can occur when hydrogen enters steel as a result of the reduction reaction on a metal cathode. Single-atom nascent hydrogen atoms then diffuse through the metal until they meet with another atom, usually at inclusions or defects in the metal. The resultant diatomic hydrogen molecules are then too big to migrate and become trapped. Eventually a gas blister builds up and may split the metal.

Hydrogen blistering is controlled by minimizing corrosion in acidic environments. It is not a problem in neutral or caustic environments or with high-quality steels that have low impurity and inclusion levels.

Corrosion in concrete

Concrete is a widely-used structural material that is frequently reinforced with carbon steel reinforcing rods, post-tensioning cable or prestressing wires. The steel is necessary to maintain the strength of the structure, but it is subject to corrosion. The cracking associated with corrosion in concrete is a major concern in areas with marine environments and in areas which use deicing salts (Figure 8).

There are two theories on how corrosion in concrete occurs:

Both possibilities have their advocates, and it is also possible that corrosion in concrete can occur either way. The mechanism isn't truly important, the corrosion leads to damage, and the damage must be controlled.

In new construction, corrosion in concrete is usually controlled by embedding the steel deep enough so that chemicals from the surface don't reach the steel (adequate depth of cover). Other controls include keeping the water/cement ratio below 0.4, having a high cement factor, proper detailing to prevent cracking and ponding, and the use of chemical admixtures. These methods are very effective, and most concrete structures, even in marine environments, do not corrode.

Unfortunately, some concrete structures do corrode. When this happens, remedial action can include repairing the cracked and spalled concrete, coating the surface to prevent further entry of corrosive chemicals into the structure, and cathodic protection, an electrical means of corrosion control.

Microbial corrosion

Microbial corrosion (also called microbiologically-influenced corrosion or MIC) is corrosion that is caused by the presence and activities of microbes (Figure 9). This corrosion can take many forms and can be controlled by biocides or by conventional corrosion control methods.

There are a number of mechanisms associated with this form of corrosion, and detailed explanations are available at the web sites listed at the bottom of this section. Most MIC takes the form of pits that form underneath colonies of living organic matter and mineral and biodeposits. This biofilm creates a protective environment where conditions can become quite corrosive and corrosion is accelerated.

MIC can be a serious problem in stagnant water systems. The use of biocides and mechanical cleaning methods can reduce MIC, but anywhere where stagnant water is likely to collect is a location where MIC can occur.

Corrosion can only occur if some other chemical is present to be reduced. In most environments, the chemical that is reduced is either dissolved oxygen or hydrogen ions in acids. In anaerobic conditions (no oxygen or air present), some bacteria (anaerobic bacteria) can thrive. These bacteria can provide the reducible chemicals that allow corrosion to occur. That's how the limited corrosion that was found on the hull of the Titanic occurred.

Much microbial corrosion involves anaerobic or stagnant conditions, but it can also be found on structures exposed to air.

In addition to the use of corrosion resistant alloys, control of MIC involves the use of biocides and cleaning methods that remove deposits from metal surfaces. Bacteria are very small, and it is often very difficult to get a metal system smooth enough and clean enough to prevent MIC.