lubrication

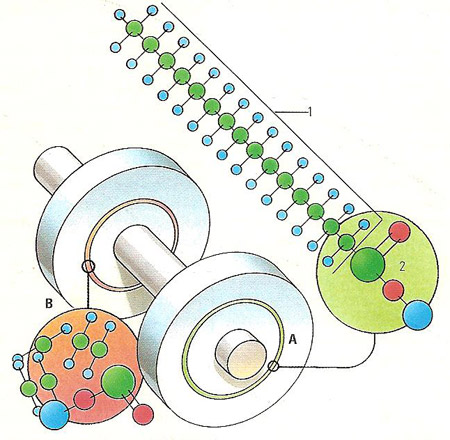

Lubricants are used to reduce wear between surfaces in rubbing contact, such as bearings. A film of oil between the bearing surfaces prevents metal contacting metal and reduces friction (A). Refined mineral oils have small quantities of fatty acids (1) added as boundary lubricants; the reactive carboxyl group at one end of the molecule (2) attracts it to the metal surface so that it stands on end. Oils for different uses usually have different viscosities, but multigrade oils contain additives which allow them to withstand the range of temperatures and pressures encountered as bearings change speed. However, with time, oil molecules degrade, breakdown, or undergo chemical change and become less effective and should be replaced or replenished (B).

Lubrication is the introduction of a thin-film of lubricant – usually a semiviscous fluid – between two surfaces moving relative to each other, in order to minimize friction and abrasive wear. In particular, bearings are lubricated in engines and other machinery. Liquid lubricants are most common, usually petroleum fractions, being cheap, easy to introduce, and good at cooling the parts. The viscosity is tailored to the load, being made high enough to maintain the film yet not so high that power is lost. Multigrade oils cover a range of viscosity. The viscosity index represents the constancy of the viscosity over the usual temperature range – a desirable feature.

Synthetic oils, including silicones, are used for high-temperature and other special applications. Greases – normally oils thickened with soap, fats, or waxes – are preferred where the lubricant has to stay in place without being sealed in. Solid lubricants, usually applied with a binder, are soft, layered solids including graphite, molybdenite, talc, and boron nitride. Teflon, with its uniquely low coefficient of friction, is used for self-lubricating bearings. Rarely air or another gas is used as a lubricant. Additives to liquid lubricants include antioxidants, detergents, pour-point depressants (increasing low-temperature fluidity), and polymers to improve the viscosity index.